Blog

How to Clean Commercial Hood Filters and Vents

Operating a commercial kitchen means you’re probably aware of hood vents and what they do. You also probably know all about what a job cleaning their filters can be. Venting the heat from your cooktops, grills, and frying stations means they also accumulate a lot of grease. This can lead to a potentially dangerous situation, ... How to Clean Commercial Hood Filters and Vents

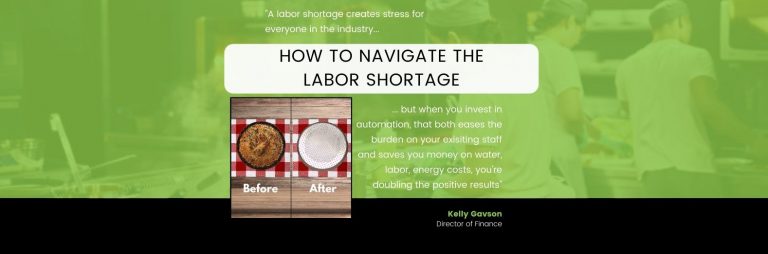

Survive Labor Shortages with These Creative Solutions

The struggle of being short staffed in the restaurant industry is a universal one. Attempting to run your store, even on a moderately busy shift, while shorthanded is incredibly stressful for everyone involved. Restaurants across all segments have been severely affected, due to the record number of workers who have quit the industry throughout 2021. So, how ... Survive Labor Shortages with These Creative Solutions

Visible Evidence of Cleanliness is Key for Restaurant Success

COVID-19 has had a significant impact on the restaurant and foodservice industry. With a loss of more than$25 billion in sales and 3 million jobs in the first month of the coronavirus shutdown, businesses must find the proper roadmap to re-open their restaurants in a way that makes customers and employees feel safe. While takeout ... Visible Evidence of Cleanliness is Key for Restaurant Success

Pandemic Surprises Food Industry – Food Trucks are Growing

With curfews, lockdowns, and an ever-present public health crisis, those in the food industry face a tricky business landscape. Finding a balance between keeping customers feeling safe, making a profit, and following local guidelines can be challenging and even detrimental to many businesses. However, exciting discovery in the Pandemic era is the popularity and profit ... Pandemic Surprises Food Industry – Food Trucks are Growing

Back of House Efficiency a Must for The Ever-Changing Restaurant Industry

Fifty-two percent of adults claim that ordering takeout or delivery is an essential part of their lifestyle. The response by many restaurants to this dramatic shift is to create ghost kitchens. Ordering from ghost kitchens has increased as the pandemic eliminated regular dining options, and people feel safer eating at home or in a public location. ... Back of House Efficiency a Must for The Ever-Changing Restaurant Industry

New Website and FOG Tank at the National Restaurant Association Show

New Website and FOG Tank at the National Restaurant Association Show We are excited to introduce our brand new website, which features new videos, before and after photos, and product details that will help you learn more about the FOG Tank. The FOG Tank is a fully insulated and thermostatically controlled stainless steel soak tank ... New Website and FOG Tank at the National Restaurant Association Show

FOG Tank Meets Top Chef Fabio Viviani

We had a great time at the 2014 National Restaurant Association Show in Chicago! It was wonderful to speak to all of the chefs, restaurant owners, and managers that stopped by our booth. We also got a special surprise when we were able to meet Chef Fabio Viviani, who you may recognize from Season 5 ... FOG Tank Meets Top Chef Fabio Viviani

7 tips for cleaning commercial kitchen floors

We can help you clean all of your kitchen equipment, but to have a truly clean kitchen you can’t forget about the floor. Read on for some advice from restaurant-hospitality.com. Energy is low by the time your back-of-the-house staffers reach the end of a long shift, often causing routine kitchen clean-up tasks to be performed ... 7 tips for cleaning commercial kitchen floors

Is Your Restaurant’s Spotless Kitchen Really Clean?

Let’s be honest, just because your restaurant’s kitchen looks clean, doesn’t mean that it IS clean. One of the tedious aspects of fighting illness-causing germs and bacteria is that you can’t see these invisible but formidable enemies. They lurk in your produce, spread like wildfire, and attack when and where you’re most vulnerable. But don’t ... Is Your Restaurant’s Spotless Kitchen Really Clean?

The Perfect 4th of July Burger

Back in 1776, the United States of America declared its independence from the Kingdom of Great Britain on July 4th. Today, Independence Day is a nationwide holiday typically associated with fireworks, parades, family reunions, concerts, carnivals, beverages and food. Lots and lots of food. According to Heavy, Americans put down an astonishing 150 million hotdogs and ... The Perfect 4th of July Burger

6 Best Food Cities and Their Restaurant Weeks

Ever wonder when America’s best food cities hold their restaurant weeks? Wonder no more, we have that info for you right here! If you love to eat as much as we do, we suggest you check this out. Because different cities host a number of restaurant weeks throughout the year, we’re going to focus on the ones ... 6 Best Food Cities and Their Restaurant Weeks

How to Plan Your Restaurant Startup

If you love food – like, more than life itself – you may want to consider a restaurant startup. First things first. You have to figure out exactly what kind of establishment you want to have. While you can go in any direction you choose, generally, a fast-food or family operated restaurant startup is best for beginners. ... How to Plan Your Restaurant Startup